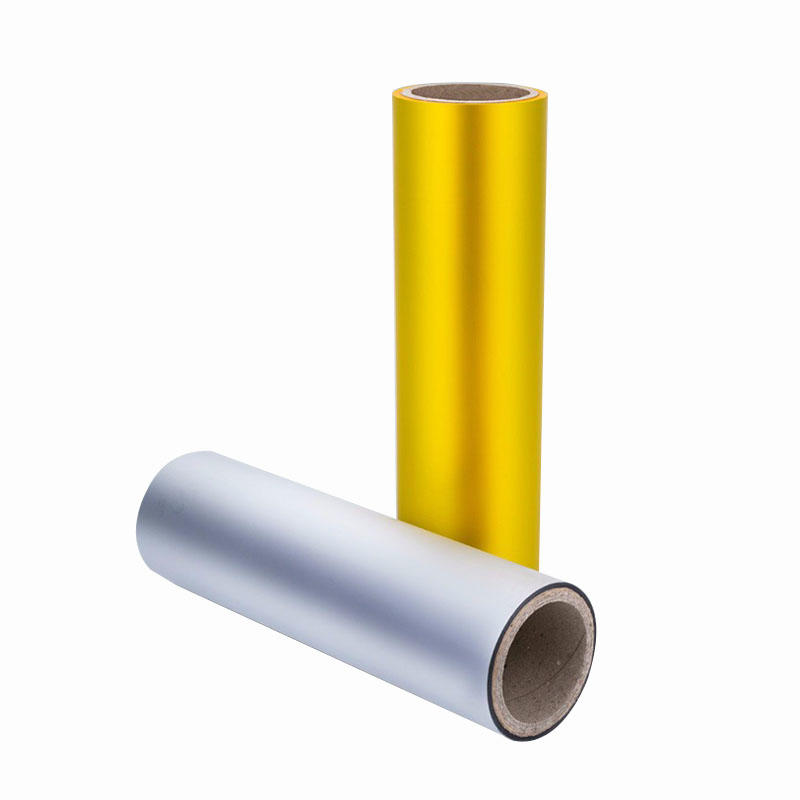

30mic Soft touch film with different colors

30mic Soft touch film with different colors

PRODUCT DETAILS

Soft Touch Film/Velvet film is a film with high haze and special matt effect base on bopp thermal lamination film, it is outstanding lustre even after laminating, with special feeling of smooth Velvet and leather touch.

TECHNICAL SPECIFICATIONS

| Item | 30mic | |||||

| Color | Transparent | Black | Red | Yellow | Blue | |

| Thickness (micron) | OPP | 15 | 15 | 15 | 15 | 15 |

| EVA | 12 | 12 | 12 | 12 | 12 | |

| SOFT TOUCH | 3 | 3 | 3 | 3 | 3 | |

| Melting temperature | From 100 to 130℃ | |||||

| Corona treatment | 38-42dynes | |||||

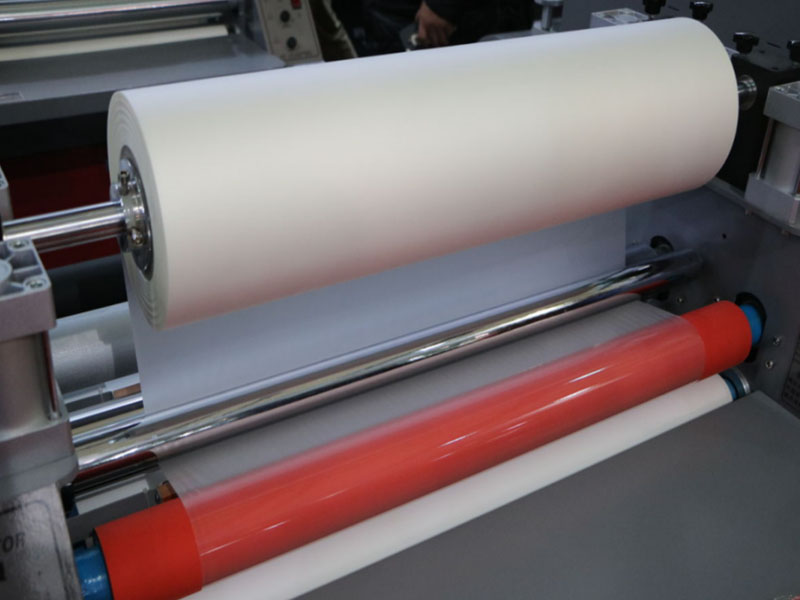

| Lamination Equipment | dry and wet laminator | |||||

| Available size | Width: 200mm-1900mm Length: 200m-4000m | |||||

| Paper core (inches) | 1(25mm), 2.25(57mm), 3(76mm) | |||||

| Average grammage | ㎡/kg | 37 | 37 | 37 | 37 | 37 |

| Remark | Different color is available to produce | |||||

APPLICATIONS

Soft Touch Film has a wide product application field, suitable for advertising prints, digital prints and luxury packaging Any ordinary hot laminating machines

a.Black color soft touch film for paper box and bags

b.pink color soft touch film for paper box and bags

c.gold color soft touch film for paper box and bags

c.transparent soft touch film for paper box and bags

Copyright © 2025 China Top-In Film Manufacture Co.,Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.