Bopp holographic film with Eva glue

Bopp holographic film with Eva glue

PRODUCT DETAILS

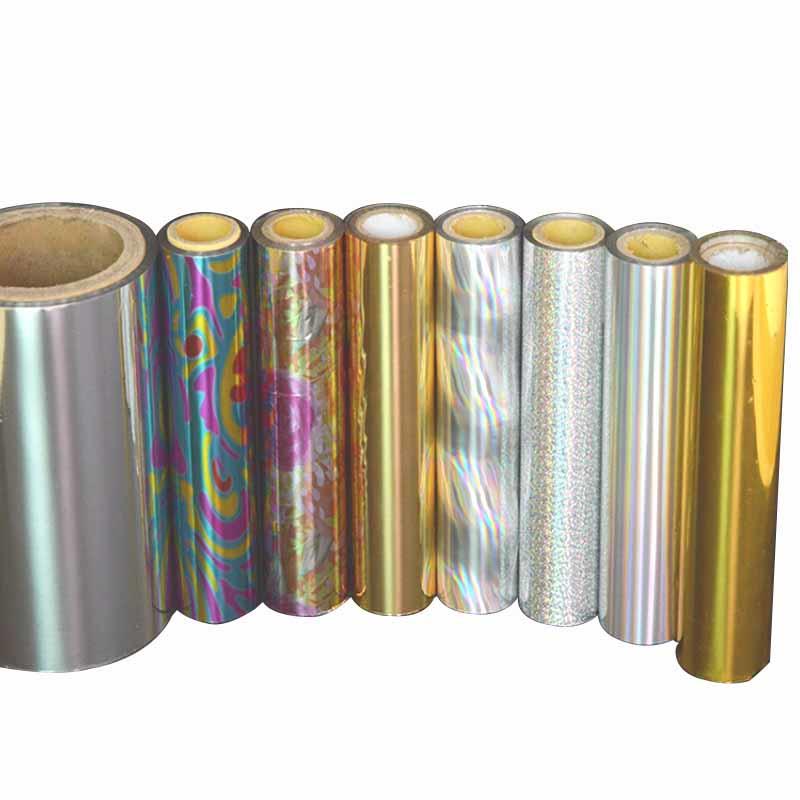

Holographic OPP film can be used exactly the same way as plain varnishing film. But in addition to the protection benefit, holography brings its own refractive and kinetic effects to enhance the visual appeal.

As a cost-effective material, holographic OPP can also be used to laminate to cardboard. It can also replace plain OPP film to make flexible packages to boost the shelf appearance of products.

TECHNICAL SPECIFICATIONS

| Item | 20mic | 23mic | 20mic | 23mic | |

| Color | Transparent | Transparent | Untransparent | Untransparent | |

| Thickness (micron) | Total | 20 | 23 | 20 | 23 |

| OPP | 12 | 15 | 12 | 15 | |

| EVA | 8 | 8 | 8 | 8 | |

| Melting temperature | From 100 to 130℃ | ||||

| Corona treatment | 38-42dynes | ||||

| Lamination Equipment | dry and wet laminator | ||||

| Available size | Width: 200mm-1900mm Length: 200m-4000m | ||||

| Paper core (inches) | 1(25mm), 2.25(57mm), 3(76mm) | ||||

| Average Grammage | ㎡/kg | 53 | 46 | 53 | 46 |

| Remark | 42 Patterns | ||||

APPLICATIONS

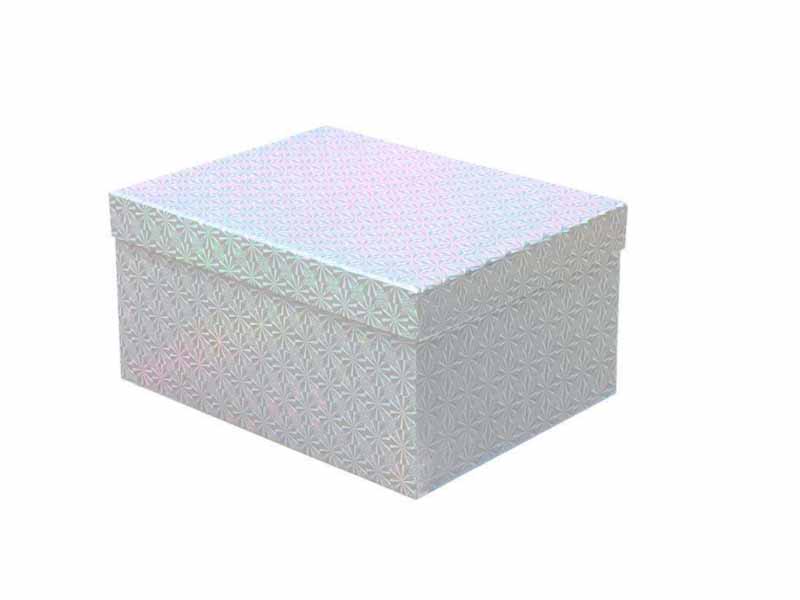

Holographic film is popular in cigarette packets,toothpaste boxes,medicine boxes, gift-wrapping paper,the festal handicraft,fireworks packaging, pocker and glitter market.

Bopp Laser film used for shopping bags

Bopp Laser film used for gift boxes

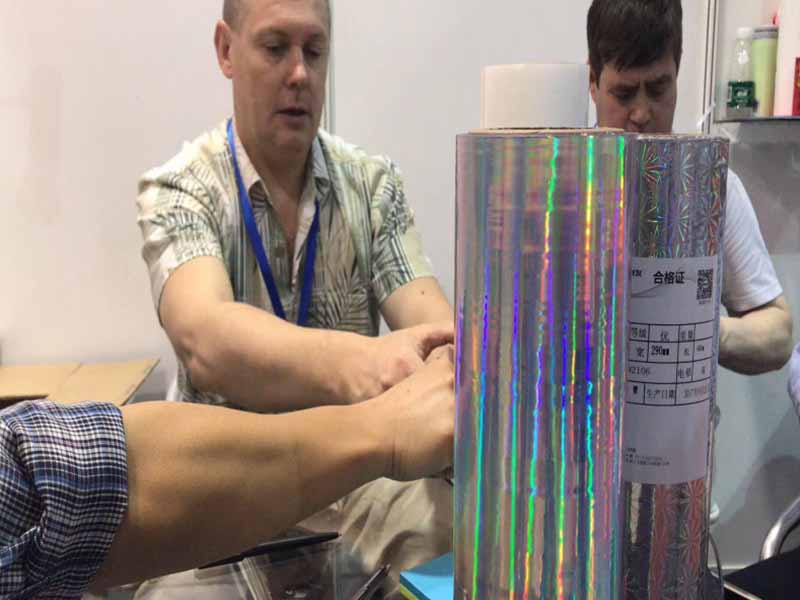

In Shanghai All in Print Exhibition customers are very interested in Bopp Laser film

Copyright © 2025 China Top-In Film Manufacture Co.,Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.