Bopp+Eva Thermal laminating film Glossy&Matt 15mic-30mic

Bopp+Eva Thermal laminating film Glossy&Matt 15mic-30mic

PRODUCT DETAILS

Bopp thermal laminating film is an environmental material for paper printing Industry. It is constructed with BOPP basic film and low melt copolymer (EVA glue) adhesive with the following advantages: easy to operate on the laminating machine, shorter operation time and labor savings; suitable for ordinary hot Laminating.

BOPP Thermal Lamination Film has two classifications: Glossy and Matt

Bopp Glossy film: good at transparency

Bopp Matt film: good for spot UV and hot stamping

TECHNICAL SPECIFICATIONS

| Item | 18mic | 21mic | 24mic | 27mic | 18mic | 21mic | 24mic | 27mic | |

| Film type | Gloss | Gloss | Gloss | Gloss | Matt | Matt | Matt | Matt | |

| Thickness (micron) | TOTAL | 18 | 21 | 24 | 27 | 18 | 20 | 24 | 27 |

| OPP | 12 | 12 | 15 | 15 | 12 | 12 | 15 | 15 | |

| EVA | 6 | 9 | 9 | 12 | 6 | 8 | 9 | 12 | |

| Melting temperature | From 100 to 130℃ | ||||||||

| Corona treatment | 38-42dynes | ||||||||

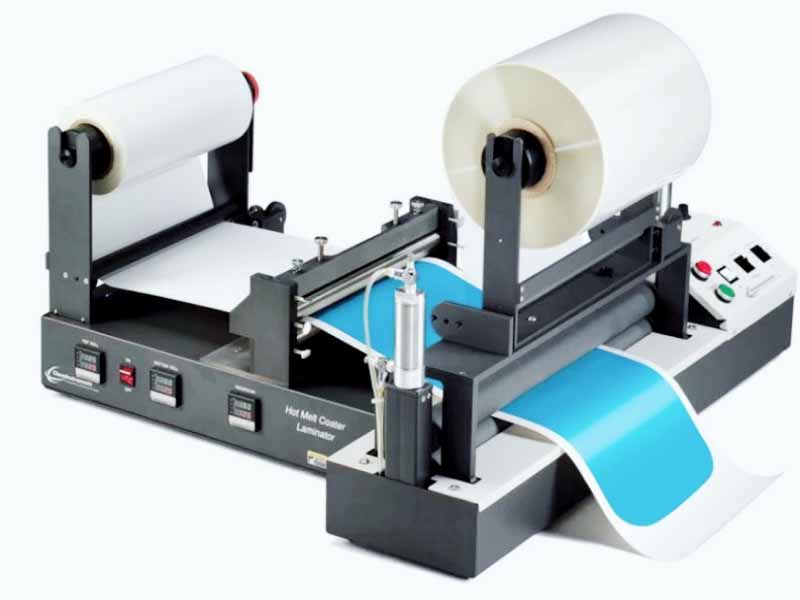

| Lamination Equipment | dry and wet laminator | ||||||||

| Available size | Width: 200mm-1900mm Length: 200m-4000m | ||||||||

| Paper core (inches) | 1(25mm), 2.25(57mm), 3(76mm) | ||||||||

| Average Grammage | ㎡/kg | 61.77 | 54.3 | 47.2 | 41.7 | 64.1 | 56 | 50 | 43.86 |

APPLICATIONS

Bopp hot lamination film is widely used in picture albums, book covers, posters, magazines, paper box, brochures and food packaging.

Bopp thermal lamination film is workable for ordinary hot laminator.

Bopp thermal lamination film used for magazine laminating.

Bopp thermal lamination film used for high class paper box and bags laminating.

the thickness is thinner as 27mic,before is 35mic.

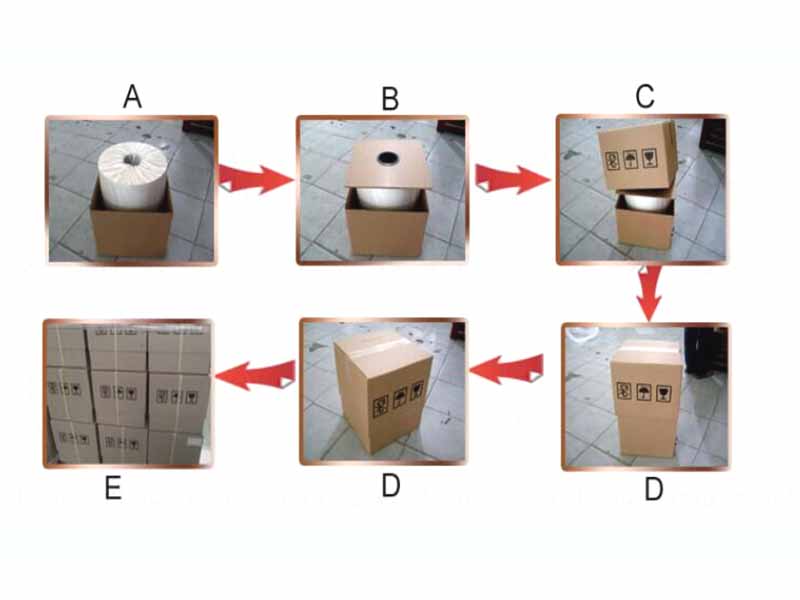

ABOUT PACKING

a.For 2000m-3000m roll, we pack 1 roll in a carton

b. For export standard packing is cartons+pallets

c.For LCL loading we mark on every pallet.

d.For 40ft container usually can loads 20-22 pallets, for 20ft container is 10-12 pallets.

Copyright © 2025 China Top-In Film Manufacture Co.,Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.