Heat transfer toner foil for digital printing in various colors

Heat transfer toner foil for digital printing in various colors

PRODUCT DETAILS

Digital transfer foil fusing series has hot stamping effect without mould. It transfers image on the paper surface, which is printed by digital toner printer.

Different patterns have different unique effects in spot locations or full coverage. The foil fusing can be used up to 3~4 times!

TECHNICAL SPECIFICATIONS

| Digital Toner/Sleeking Film | |||

| Pattern | 18 patterns: Hot stamping foil( Gold/silver/red/green/blue/white pain color, red/green/yellow/blue sea wave) hologram dazzle silver foil /water cube/3D lens/ rossy | ||

| cloud /wany glass/hologram hexagon/ Magic Mirror and UV glossy. | |||

| Temperature | Hot stamping foil: 95~100°C; other patterns 85~90°C. Various machines, speed, pressure will have difference. | ||

| Pressure | Max pressure | ||

| Usage times | Hot stamping foils: 1 time; other patterns 3~10 times. | ||

| Paper | Black cardboard, copperplate paper, iridescent paper, kraft paper, normal A4 paper, etc. | ||

| Toner Digital Printer | Konica, Xerox, HP, Heldelberg, Brother, Epson, Canon, etc. testing first is better. | ||

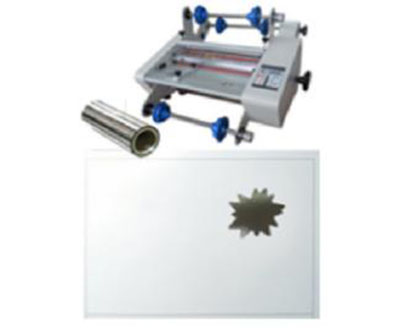

| Machine | Rewind hot laminator (better effect and reuse the film); Normal hot laminator | ||

| Ways to transmet: (for reference) |

| ||

| Notice |

| ||

| Regular Size | Width: times of 320mm, 320, 640, 960mm*200m, we also do customized size; Max Size: 1470mm*4000mm | ||

◪ Optical effects on the digital prints;

◪ Personal design with easy operation;

◪ Sleeking the Digital prints without mould;

◪ Improve the UV coating and hot stamping efficiency

APPLICATIONS

Digital toner foil works perfect on certificates, wedding cards, birthday greeting cards, invitation, wall pictures and restaurant menu.

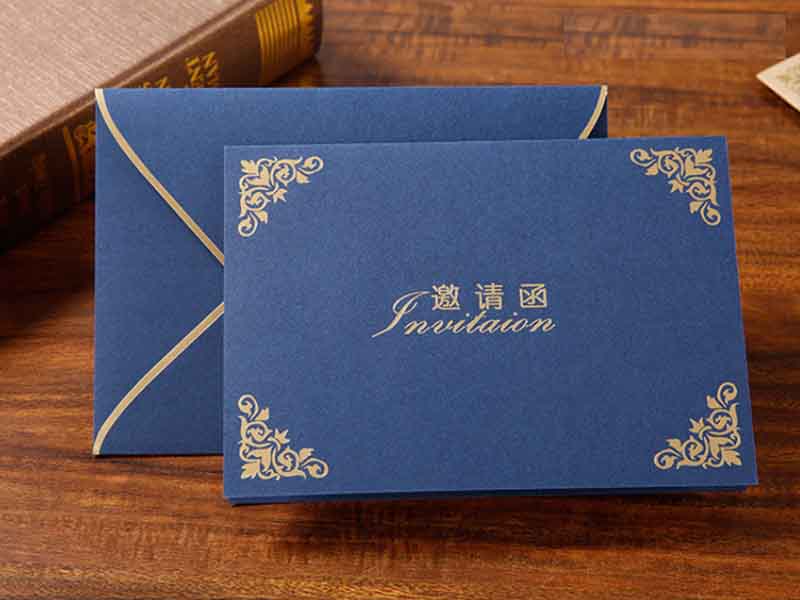

Show Room No.1: Digital toner foil used for invitation

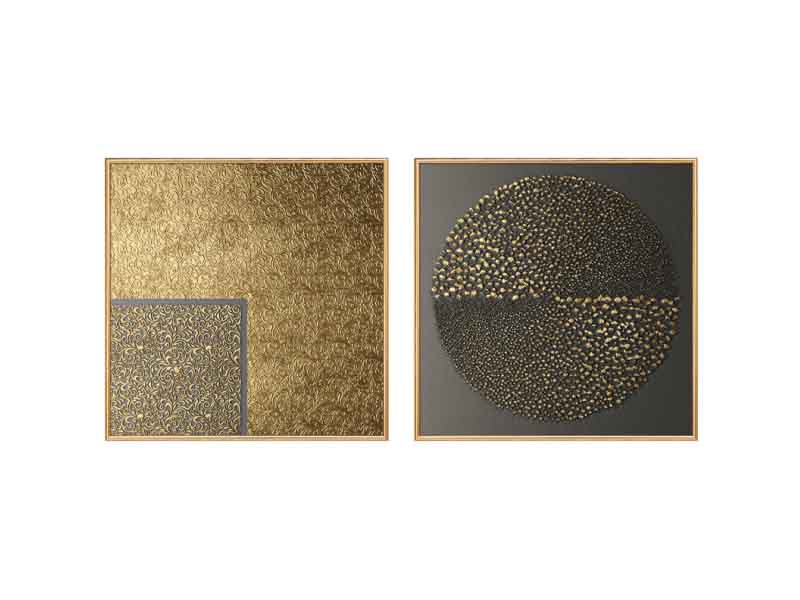

Show Room No.2: Digital toner foil used for wall pictures

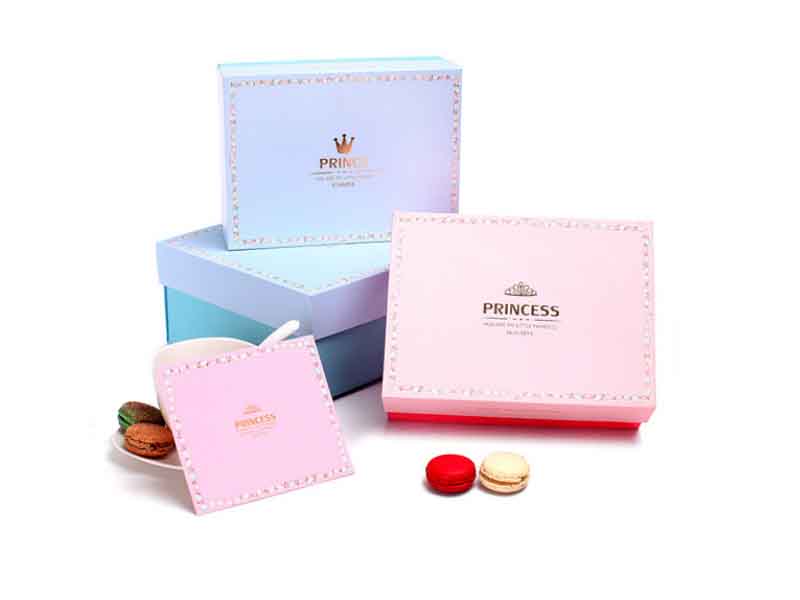

Show Room No.2: Digital toner foil used for packaging

Show Room No.2: Digital toner foil used for coaster

What's your idea for using toner foil? Contact us now for free samples!

We also have other pattern for your reference:

How to transfer the Toner foil correctly?

1.Use toner digital printer to print 100% black on area that you want effect;

2.laminate silver hot sleeking film on 1st step paper with Rewind Hot Laminator;

3.Full page colorful toner digital printing on 2nd step hot stamping effect paper;

4.And here is final hot stamping solution effect.

Copyright © 2025 China Top-In Film Manufacture Co.,Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.