About XG1080F Automatic Stamping Machine

XG1080F type automatic hot stamping machine is an integrated automatic hot stamping machine

The equipment adopts a hih-performance a-round control svstem of electromechanical intearationprofessional post-press equipment. This machine is based on the creasing and stamping machine,systematically equipped with automatic paper feeding and receiving mechanism and PLC controller toachieve the purpose of fully automatic stamping and creasing.This machine has the outstanding advantages of beautiful shape, easy operation, high efficiency, stableperformance, and safe and reliable use, which greatly reduces the user's labor intensity and operationtechnology, reduces labor cost, improves the finished product rate and consistency of hot stamping, it isthe ideal automatic professional equipment for larae and medium-sized printing companies orprofessional post-press departments.As trademarks, wine boxes, and gift boxes, can be on this machine for ordinary hot stamping as well asembossing creasina. ln order to get rich in the three-dimensional sense, exauisite and beautiful printinoproducts. This machine is designed and developed by our factory, with 5 national invention patents and24 utility model patents.

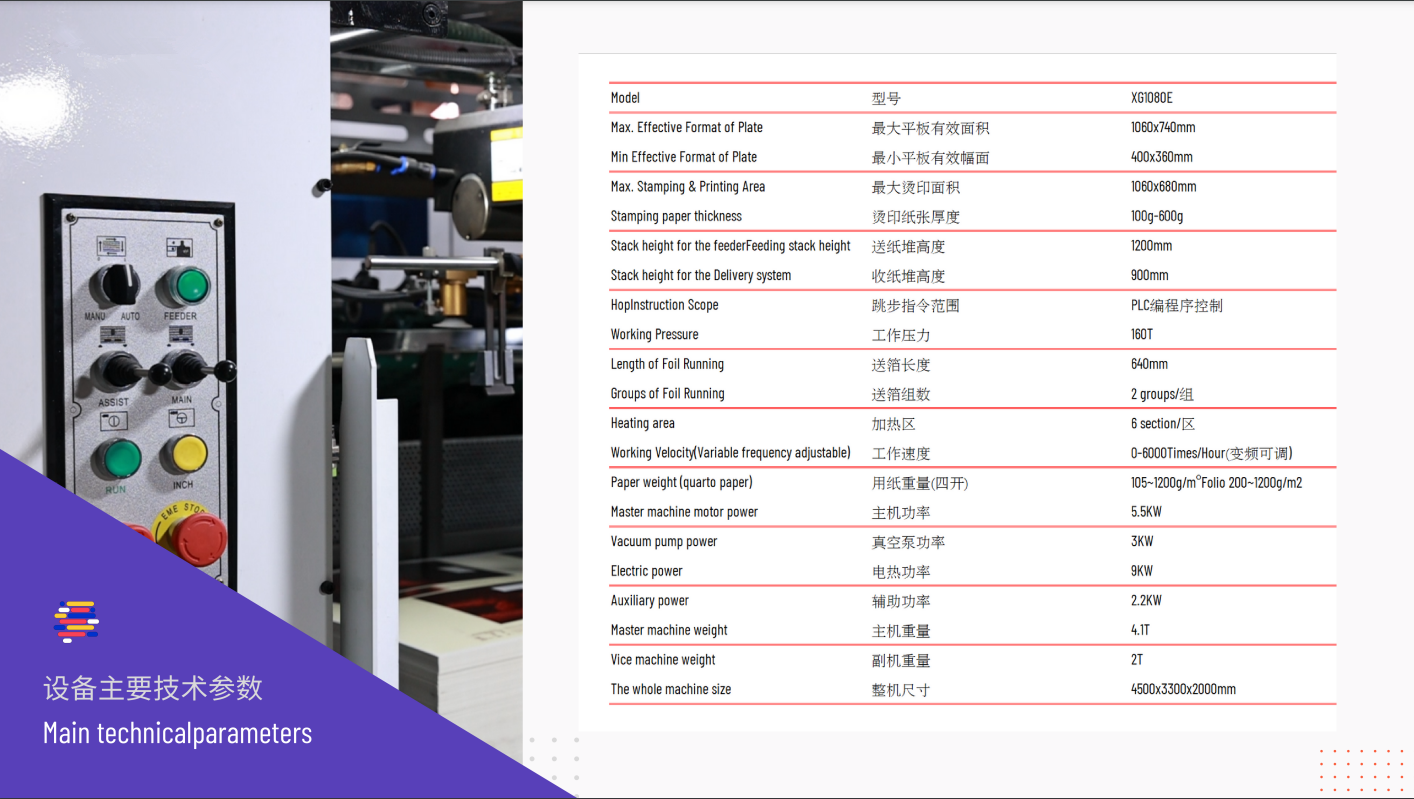

TECHNICAL SPECIFICATIONS:

ADVANTAGES:

Specialized Feida

Quick change foils

Fiber optic tracking system

Combination lifter

EQUIPMENT DETAILS:

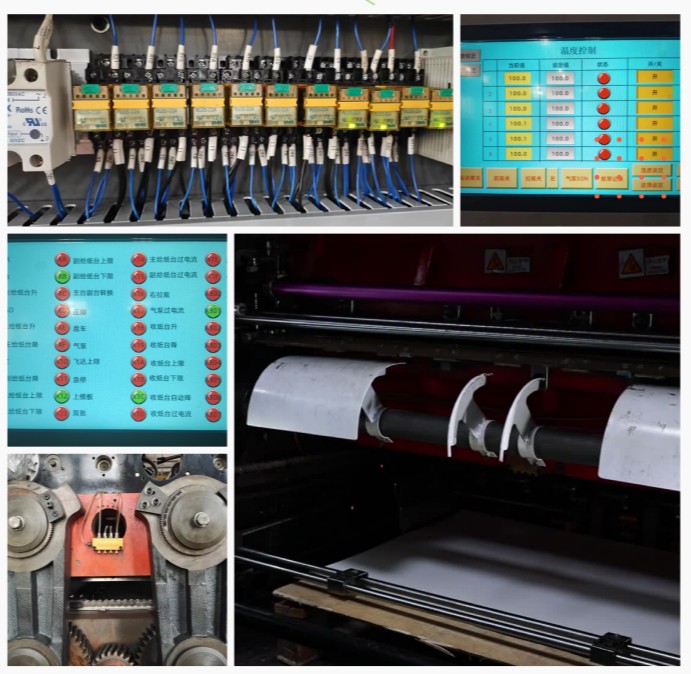

1. This machine adopts an imported temperature module and solid staterelay combination to make the temperature difference control in the minimum value.

2. All-round circuit control system, can detect and sense the mechanicaand electrical factual condition.

3.Receiving and releasing the material motor frequency conversion speed control protection, the main machine big frequency conversion speed control, and servo feed foil paper

4. Paper collection using the peel rotary (roller rotation) method, so that the hot stamping paper and paper easily separated, not like the traditional hot stamping machine air compressor blowing separation. which requires a high-power air compressor has been supplying air to the equipment,high costs, not environmentally friendly

5. flat pressure adiustment using four-link eccentric wheel adiustment front and rear pressure adjustment.

FINISHED PRODUCT:

Copyright © 2025 China Top-In Film Manufacture Co.,Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.